VIBRATION SENSOR ERROR

Cause

The vibration sensor is damaged or has experienced excessive vibration.

Solution

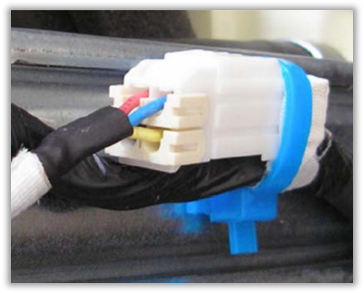

Check for loose connections at vibration sensor and Main PCB and possible damage to harness.

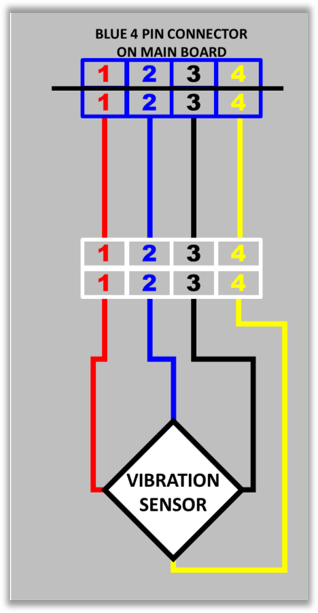

Check for 5Vdc on Red to Black wires.

DETAILS BELOW:

uS or u5 Error Code (Front Load Washer)

Initial items to check as a bad vibration sensor is not always the issue:

- Have the shipping bolts been removed?

- Is the floor stable and level where the unit is in the home?

- Was the unit leveled correctly when installed?

- Is the unit installed on a pedestal? Make sure the pedestal is level with legs as short as possible. The unit should be leveled to the pedestal with the legs as short as possible. Make sure all the screws (16) are in place that attaches the washer and pedestal together. Make sure the leg locking nuts are tight.

- Is the customer loading the unit properly? Run a rinse and spin cycle with 6–8 bath towels and check the unit operation. If the unit runs normal, have the customer bring samples of the loads they have experienced an issue with and see if they are loading unlike materials together. Provide the customer education on proper loading of the machine.

- Remove the front panel. Are all tub weights mounted to the unit and bolts tight?

- Does the tub appear to lean or droop to one side? Make sure the paint on the tub springs are the same color and are installed properly. Inspect the struts for damage and rust on the shaft.

- Does the inner tub have excess side to side or up and down movement? If so, inspect the spider assembly and tub bearings for failure.

If all above items check ok then proceed to test the vibration sensor.

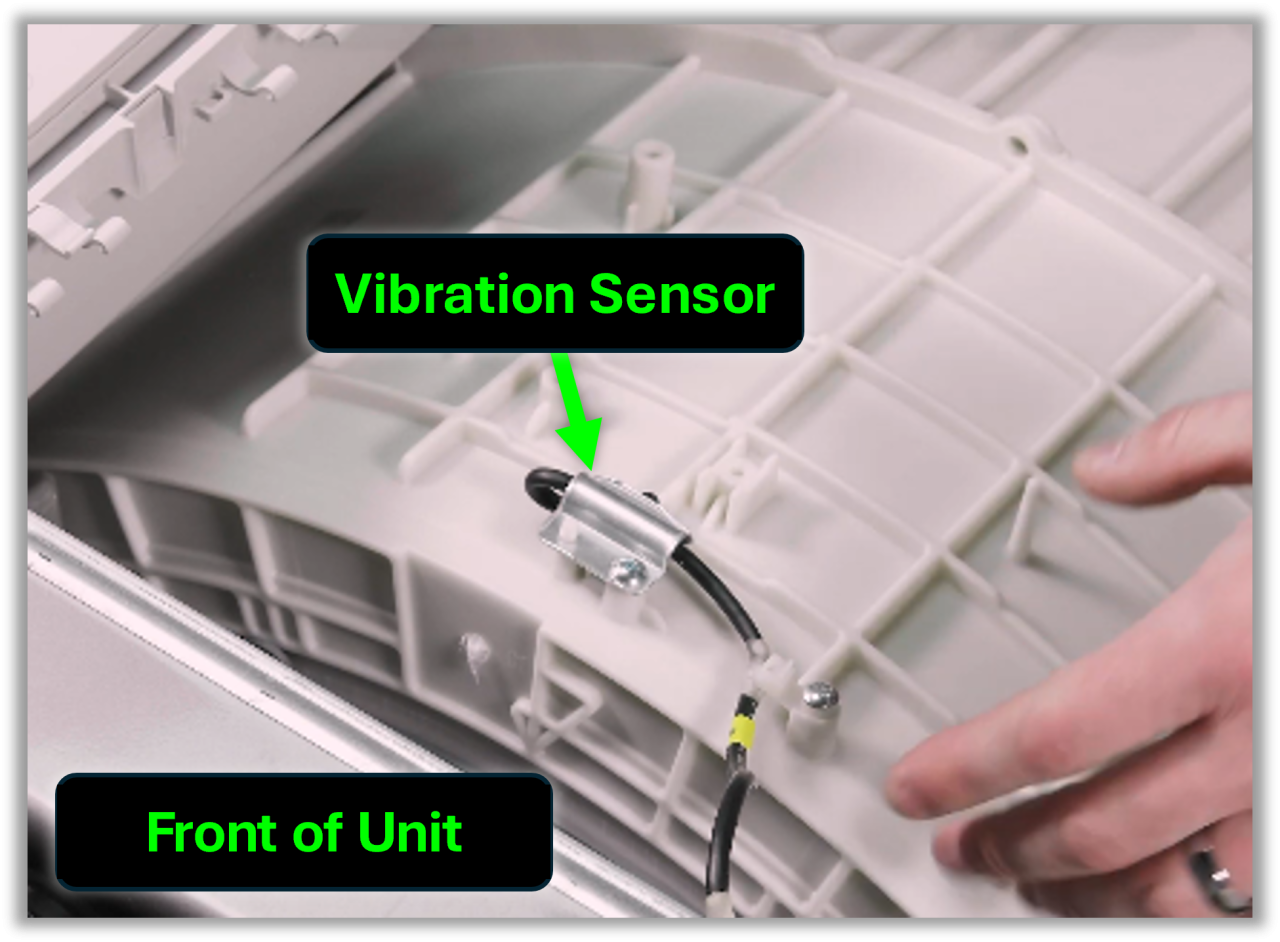

The picture below shows the location of the vibration sensor. It can be found on top of the outer tub towards the front of the unit. If the unit you are working on is a WashTower, the dryer will need to be removed to access the vibration sensor…

Note: The vibration sensor can look physically different based on model. See the picture above and below are both examples of what the vibration sensor could look like on LG washing machines. But regardless they will be located on top of the outer tub towards the front of the machine.

FROM THE MAIN BOARD

CHECK FOR 5VDC

BLACK WIRE (-) TO RED WIRE (+)

If you do not have 5Vdc with the unit powered on then replace the main board.

If you have 5Vdc at the main board then check for 5Vdc on the white connector of the sensor cable. The harness at the main board connects to the harness that comes with the sensor.

Either the harness could have an issue with a defective wire or a bent pin or the connector not firmly connected.

23 Responses

I have a U5 error code and everything checks ok, so replaced the main control and out of balance sensor. It still kicks up new code right away in a drain and spin (within a minute), what else can cause this error code ??

replace the wire harness due to instant sensor errors is due to open circuit or no voltage feedback to the main board

RNN240120068520

RNN240221014788

I need the part number for the vibration sensor. Model number WKE 100 HVA.

You need to double check for your product code but the common on for that model is EBD48922821.

I have come across this a few times and it’s usually “was working great and it’s been happening more frequently”. So in that case where it’s most likely not the sensor or the board or the harness, it is the connector coming apart during spin cycle just enough to kill power to the sensor and throw the code. You can simply put a zip tie around the connector and then verify it’s good by doing a rine and spin with 6-8 towels. If it’s the sensor or board or harness then it’ll throw the code despite thus modification.

Thanx a lot ,it helped few times,its connector indeed.

Good information / but what’s the part #

It can vary by model. Please use the parts system for lookup.

Very good helpfuf

Very good helpful

I need the original sensor EBD48922806

Sub # EBD48922821 not working.

If there is a replacement part number that means the original part subs to the new number and the old part number is no longer available.

Very good helf

what is the resitence value?

Our unit measures 2.5MΩ BK to RD, but this is not a reliable way to test this component. Instead, check for 5Vdc coming from the PCB. You can also check continuity on the other wires to confirm. If the PCB is supplying voltage, replace the sensor.

I have 5 volts dc on red to black but nothing from white. I checked the harness and it seemed fine. Will replace control and wire harness?

What is the correct vibration sensor for model WM5700HVA ?

Thank you

PN EBD48922821, If you need further assistance with parts you can go to lgparts.com or submit a zendesk ticket for parts research.

Thanks

Very use full

Where is the vibration sensor located and how can you get yo it on a lg one piece washtower?

Based on your comment, We added more contents to the article to clarify the location. The vibration sensor is located at the top of the outer tub towards the front of the unit. (Picture has been added to the article). For washtowers, the dryer will have to be separated so that you can access the vibration sensor. Hope this helps.