CLUTCH MOTOR ERROR

Cause

The Main PCB is not detecting the correct signal voltage from the clutch motor when engaging or disengaging the clutch.

Solution

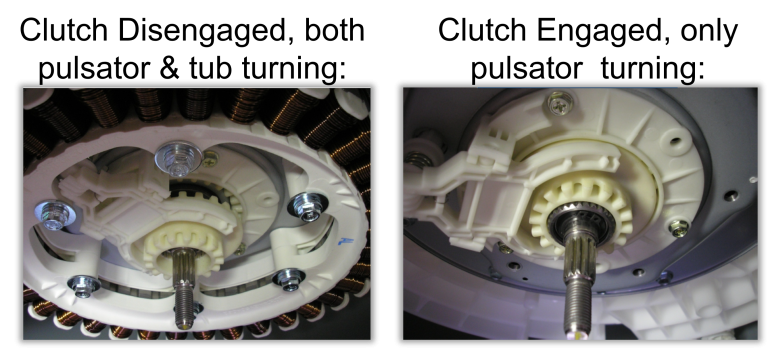

If a clicking or grinding noise is made, disassemble the pulsator and tub to check for any foreign objects (coins, keys, hair pins, etc). If a foreign object is found, remove it and retest the unit. If a noise still occurs inspect the clutch assembly for damage.

DETAILS BELOW:

Note: Earlier models used a 120 VAC clutch motor, while later and current models use 12 VDC motors.

E6 Error

Clutch Motor Error

Is the connector for the clutch motor disconnected or damaged?

If yes: Reconnect or Repair the connector.

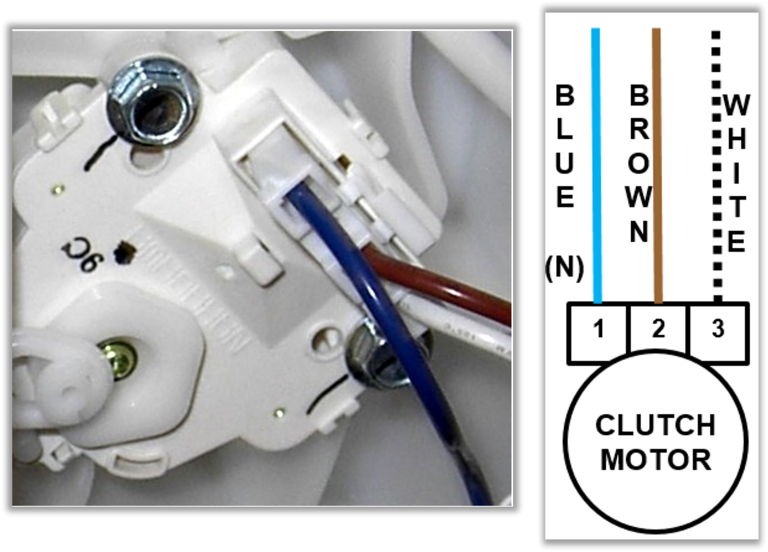

AC Clutch Motor:

Clutch Motor – 120VAC 2.1KΩ ~ 2.3KΩ

BLUE-WHITE – Energizes the clutch motor

BLUE-BROWN – Signal

Locked: Coupling down-Basket & Pulsator Engaged -120Vac BLUE-BROWN

Unlocked: Copling Up – Pulsator Only Engaged – 0Vac BLUE-BROWN

DC Clutch Motor:

New style with DC Motor: 55 Ω

Blue to White is 12vdc

Blue to Brown is 6vdc signal when locked in spin

NOTE: Earlier models were equipped with a 120Vac clutch motor, while later and current models are equipped with 12Vdc motors.

5 Responses

It’s very helpful to show connector on main board. For wiring issue..

Thanks for the comment Taj. On washers the wire colors do not change from the board to the component like we see with refrigerators and other products. So you would simply find the connector with the Blue, Brown, White wires and the readings would be the same from the board or the motor itself. Thanks.

Very thourough. I couldn’t even find this in the service manual thank you

No clicking put in a new clutch motor still no response tested voltage no voltage

Good