DRAIN NOT DETECTED OR SLOW DRAIN ERROR

Cause

Drain not detected or poor drain

Solution

Check for proper drain hose installation.

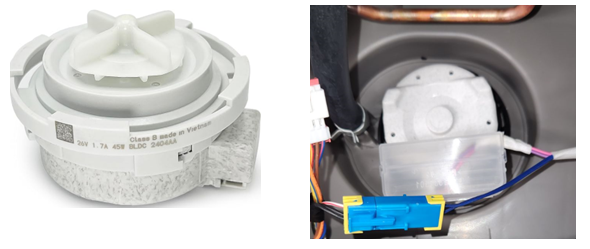

Check the Drain Pump for damage.

Drain hose for kinks or blockages.

Drain pump sump for debris.

Check the Water level sensors.

DETAILS BELOW:

Make sure the drain hose is properly installed at the back of the dryer and at the stand pipe.

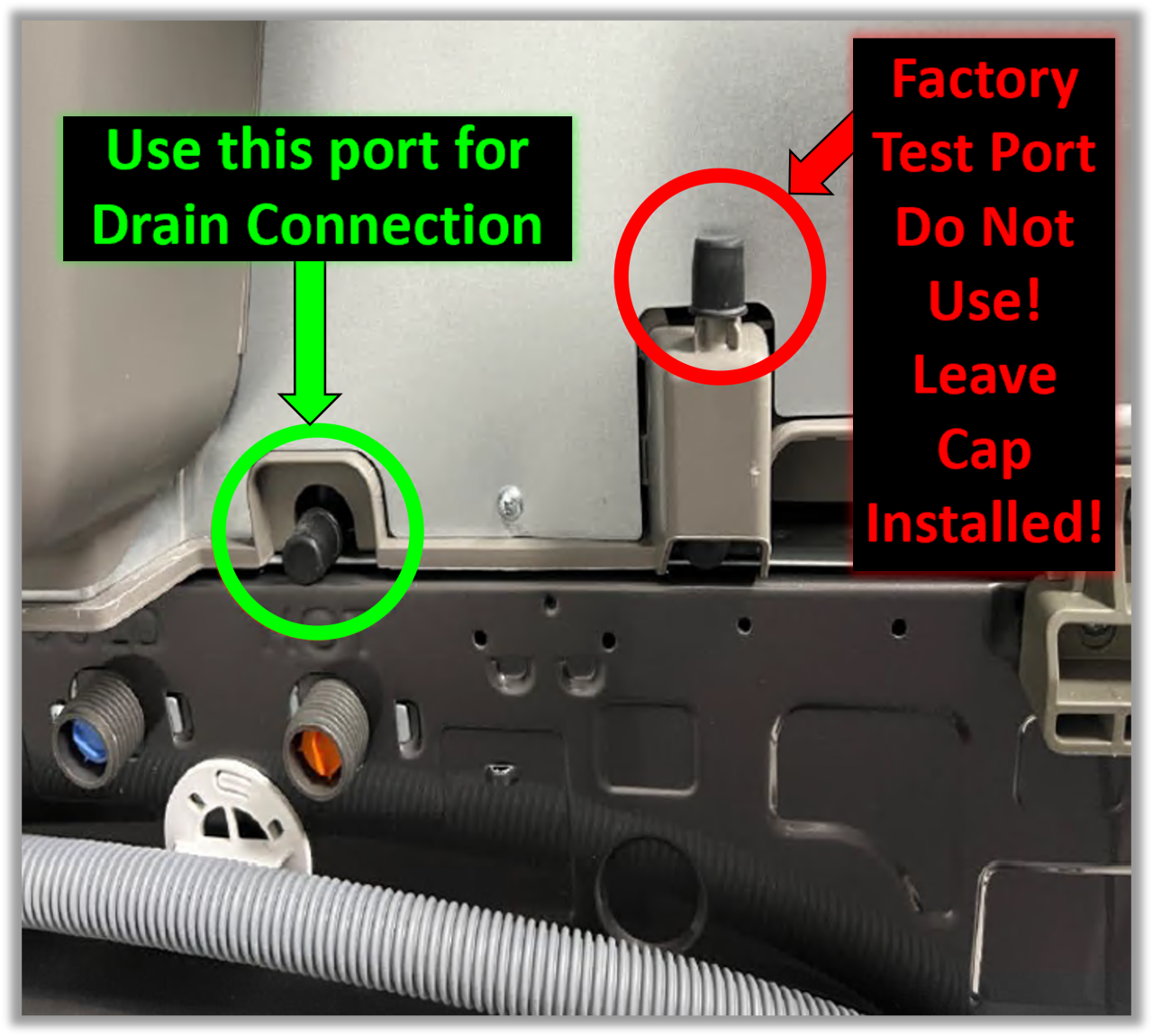

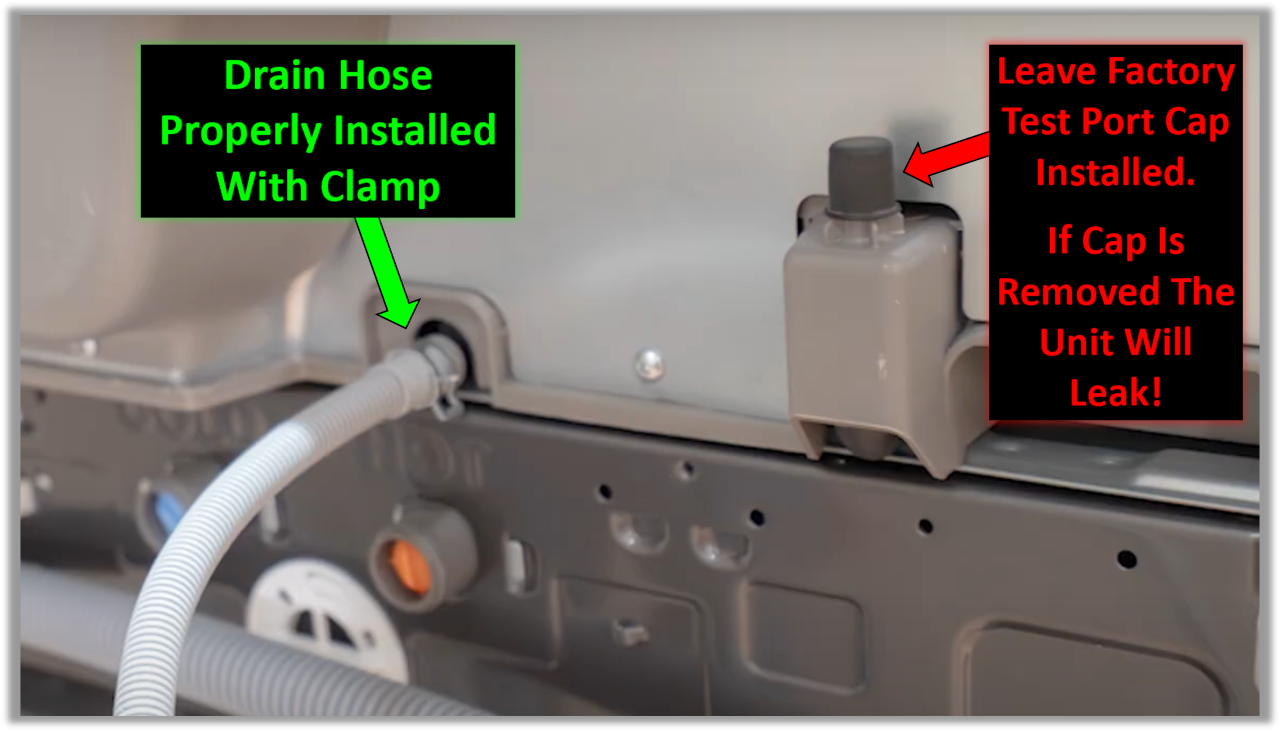

Note: Most heat pump dryers have 2 ports at the back of the unit. One port is for the drain line and the other is a factory service port. Make sure the drain hose is connected to the correct port!!!

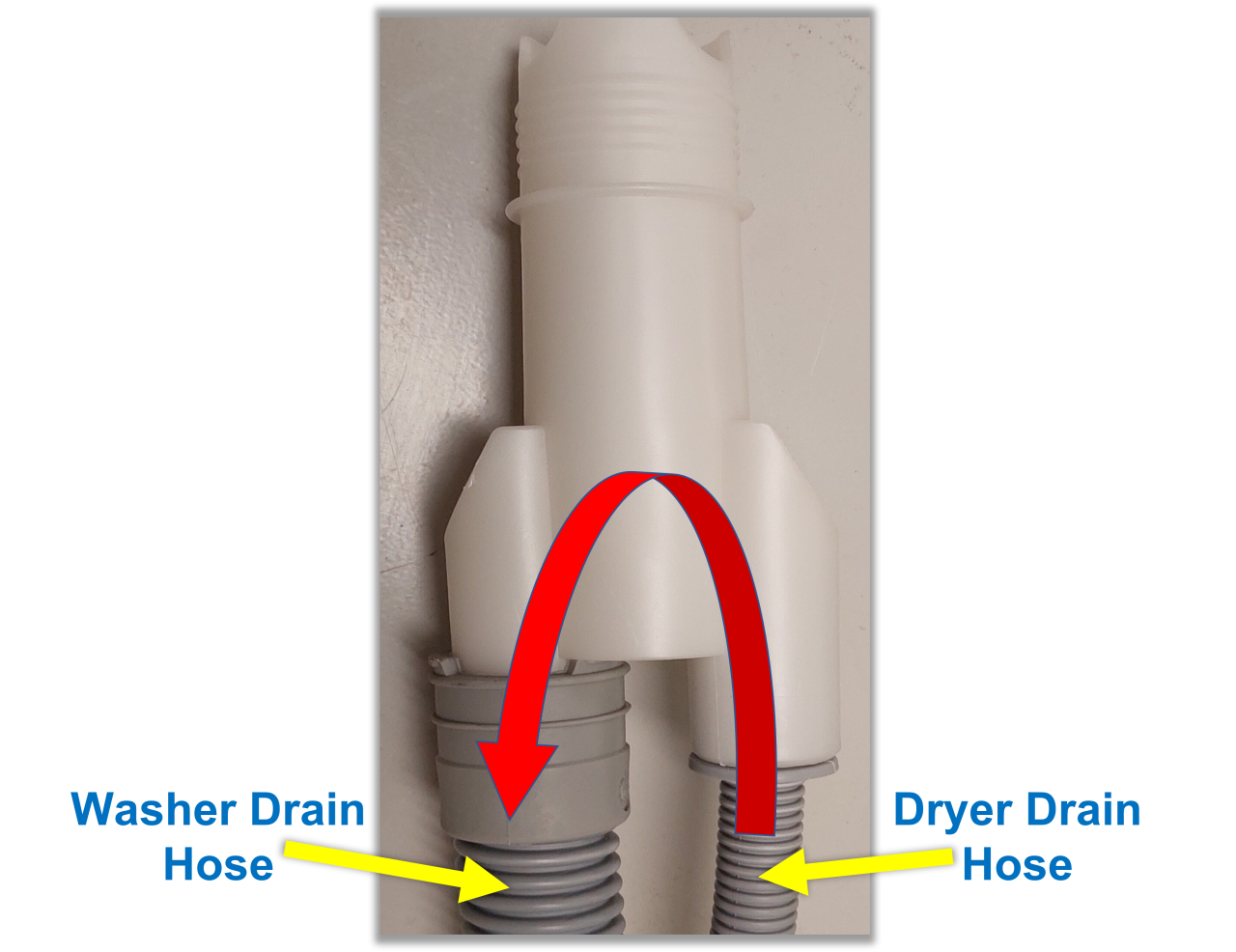

Picture with drain hose connected…

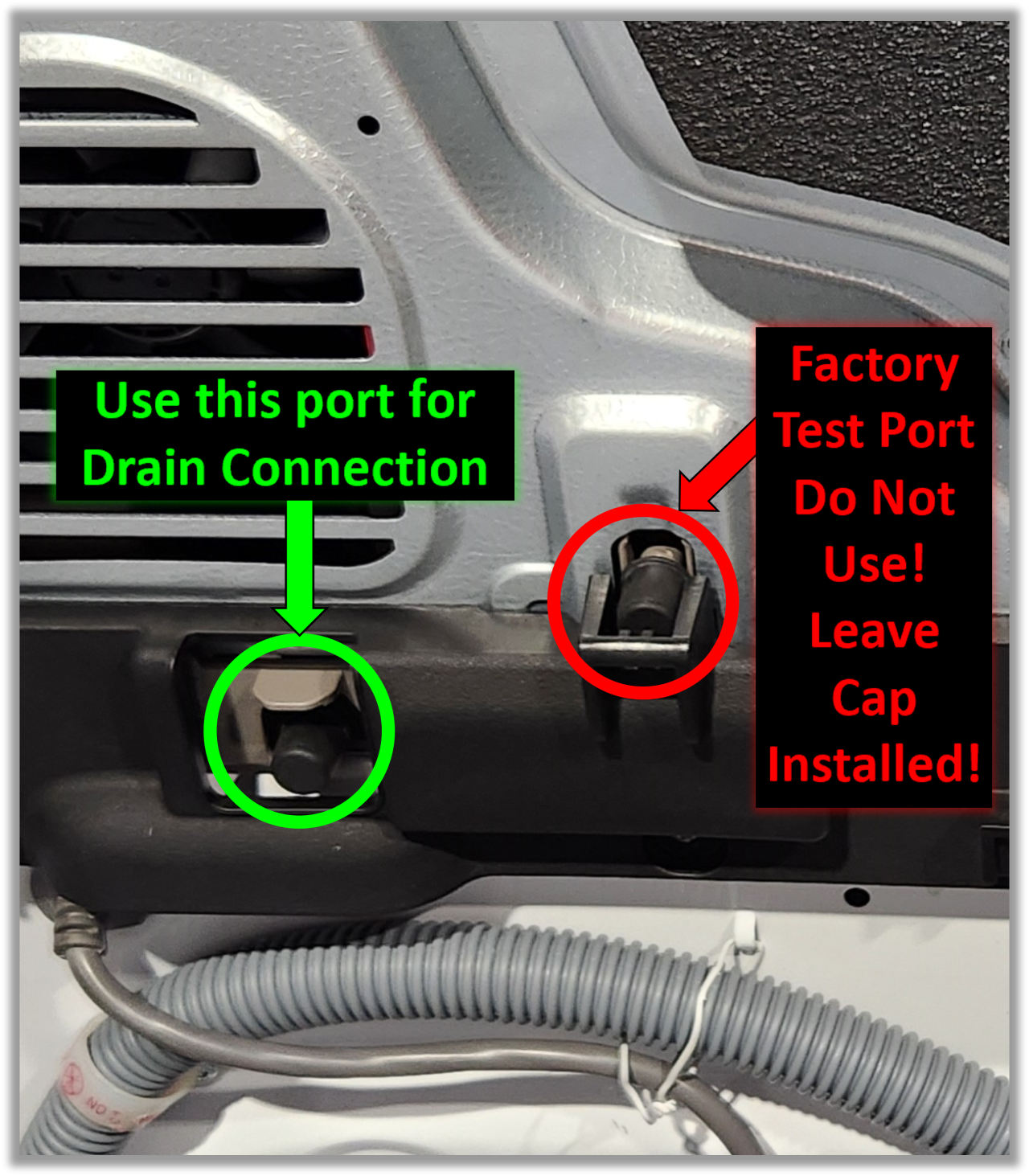

Here is another example showing a slightly different layout but the principles are the same…

If you need to order a new service port cap in the case that the customers is broken and leaking, the part number is shown below (3920ER3002A)…

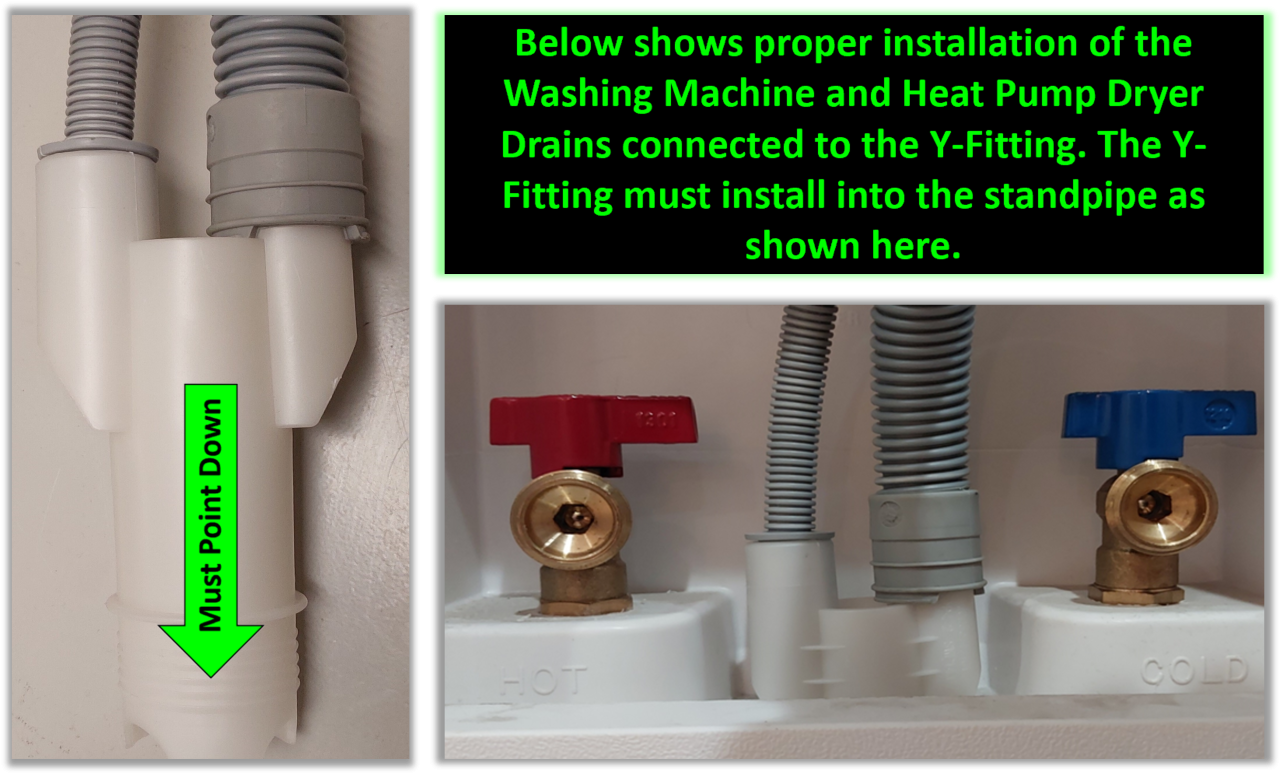

Next, make sure the drain is properly installed at the stand pipe at the wall. Failure to install properly will also cause issues. Below Shows proper installation…

Here is an example of improper installation…

If the drain is improperly installed like the above picture, water can/will fill into the washing machine while the dryer is operating…

If no drain installation issues are found then continue troubleshooting below…

The Drain Pump is a BLDC type of pump and our test model had resistance of 3.1ohm on all three legs.

Voltage read 12Vac on all three combinations of the wires at the pump.

Picture of the drain sump cover removed and the bottom of the cover.

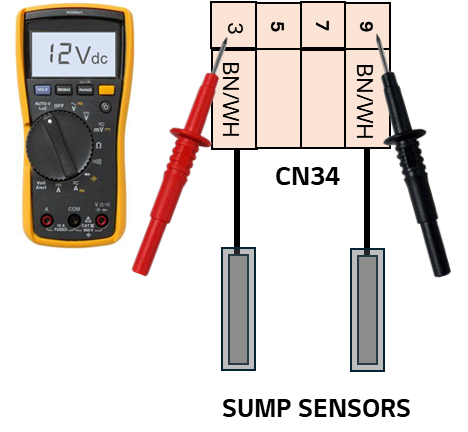

The water level sensor receives 12Vdc from the main board, and when water reaches the probes, the voltage will drop to let the Main PCB know the pump needs to activate. If there is no 12Vdc from the Main PCB replace the Main PCB. Example from WKHC252 check your machines individual diagram.

When dry the water level sensor will read 10-12Vdc, when wet the voltage will drop. When testing we read 2Vdc when the sensor was wet.

4 Responses

You should show dissable unit and the way to access to diagnostic mode

Fernando, if you go to lgrepair.com and the test mode website you should be able to find the test mode. Here is one from a WKE100, https://lgtestmodes.com/dryertest15/

If you find a model that is not covered let us know.

Thanks

Power+dry level+ wrinkle care does not activate test mode on this model DLHC6702b

I’m sorry but this is a Canadian model and we do not have any information on it.

Thanks