Linear Compressor / Main PCB Blink Codes

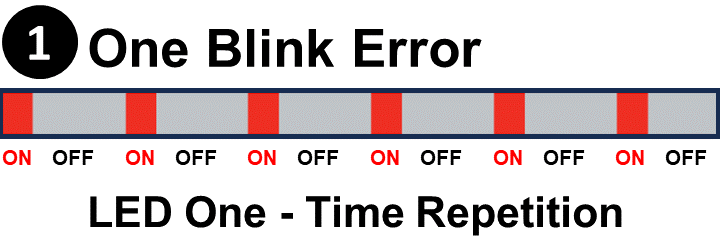

Definition: FCT0 Trip (Voltage)

Trip Logic: Abnormal IPM sensing voltage.

Reaction: Main PCB will apply power to the compressor after 30 seconds

Purpose: Main PCB circuit protection.

Most Likely Cause: Main PCB Failure.

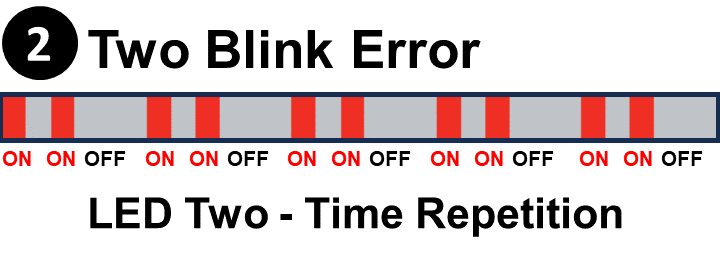

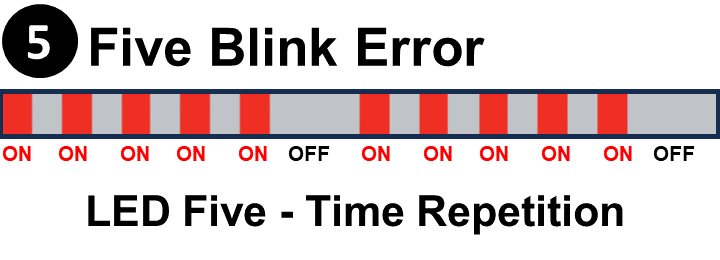

Definition: Stroke Trip

Trip Logic: Main PCB detects the compressor piston over stroke.

Reaction: Compressor is switched off. Main PCB applies power to the compressor after 60 seconds.

Purpose: Circuit protection for piston crash by abnormally large piston stroke.

Most Likely Cause: Internal compressor valve failure (can be intermittent)

Least Likely Cause: Compressor harness connection failure between the PCB and compressor or capacitor.

Other Possible Cause: Evaporator fan fault, defrost issue

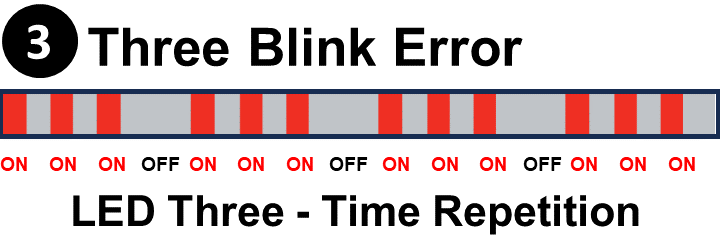

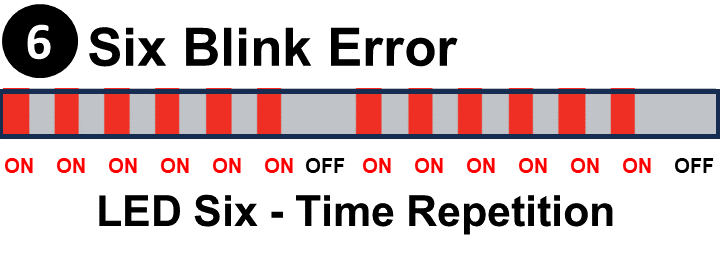

Definition: No Connection Trip

Trip Logic: Main PCB Detects open circuit to the compressor.

Reaction: Compressor is switched off. Main PCB applies power to the compressor after 40 seconds.

Purpose: Protection for the main PCB (Over-Voltage and Over-Current)

Most Likely Cause: Open compressor winding. Open harness between PCB and compressor and or capacitor.

Least Likely Cause(s): Main PCB. Compressor in deep vacuum (no charge in unit).

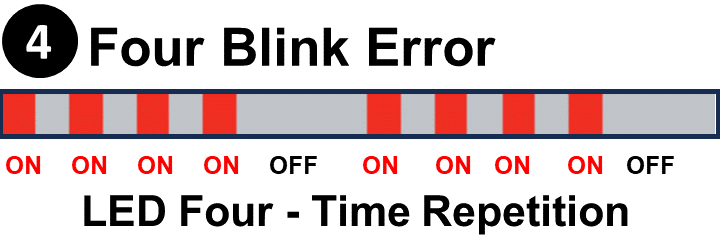

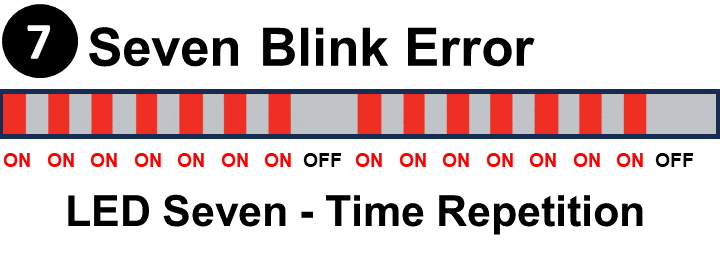

Definition: Over Voltage Trip

Trip Logic: Detection of over voltage to the Main PCB DC link (above 450vDC)

Reaction: Compressor is switched off. Main PCB applies power to the compressor after 90 seconds.

Purpose: Protect the PCB from over voltage output.

Most Likely Cause: Full or partial restriction close to the compressor outlet. Liquid forming in the outlet of the compressor.

Definition: Locked Piston Trip

Trip Logic: Main PCB fails to detect piston movement.

Reaction: Compressor is switched off. Main PCB applies power to the compressor after 150 seconds.

Purpose: Main PCB and Sealed System protection.

Most Likely Cause: Seized compressor piston, cylinder damage, internal debris, or high side restriction close to the compressor.

Least Likely Cause: Failed Main PCB.

Definition: Over Current Trip

Trip Logic: Main PCB detects over current condition on the compressor circuit.

Reaction: Compressor is switched off. The Main PCB applies power to the compressor after 6 minutes

Purpose: Main PCB and Sealed System protection

Most Likely Cause: Sealed System – Low side leak, internal compressor issue (piston damage, cylinder damage or internal debris), partial high side restriction close to the compressor.

Least Likely Cause: Long door openings, high heat load, high ambient temperatures (over 109F), poor air flow through the condenser, installation (to close to the wall), Condenser Fan Failure, or Main PCB Failure (IPM Breakdown)

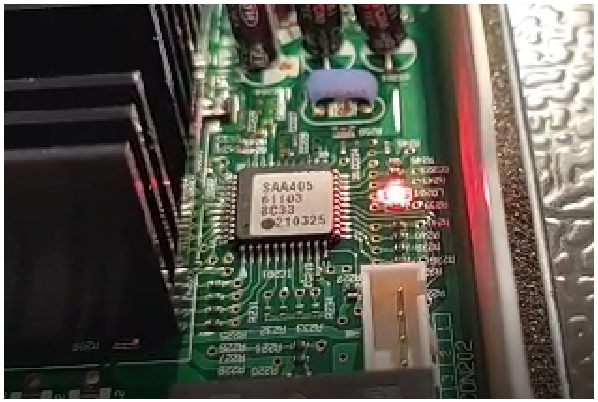

Definition: IPM Fault Trip

Trip Logic: Main PCB Detects IPM Short

Reaction: Compressor is switched off. The Main PCB applies power to the compressor every 20 seconds.

Purpose: Main PCB and Sealed System protection.

Most Likely Cause: Main PCB IPM Failure.

Least Likely Cause: Shorted compressor, compressor harness or possible sealed system problem. Wrong Compressor Installed.

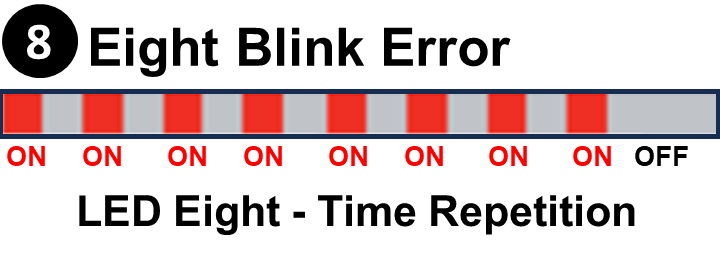

Definition: Main PCB Tx Error Trip

Trip Logic: 12vDC Communication error detected

Reaction: Only LED blinking while compressor is running. ( Compressor will continue the last order from main micom. )

Purpose: Main PCB protection from a shorted 12vDC component.

Most Likely Cause: Shorted or failed DC component. Examples : fan motor, flow meter, sub-PCB, ice maker, water tubing heater, shorted harness, ETC

Least Likely Cause: Main PBC

Not A Cause: The compressor will not cause an 8x blink code.

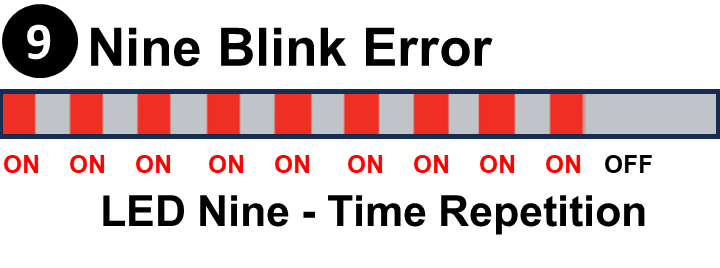

Definition: Overload Trip (Overpower)

Trip Logic: Main PCB Detected an overload condition.

Reaction: Compressor is switched off. Main PCB applies power to the compressor after 360 seconds.

Purpose: Main PCB protection from overload

Most Likely Cause: High temperature, environmental condition, condenser fan error, poor air flow, dirty condenser, internal compressor problem, IPM failure

Least Likely Cause: Main PCB

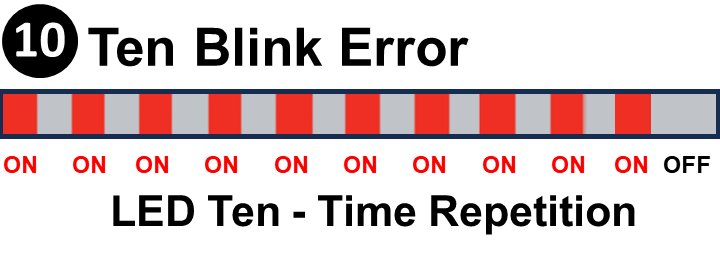

Definition: Compressor Machine Room Too Hot, Over Over 43°C / 109.4°F, (Overload)

Trip Logic: Main PCB Detected an overload condition.

Reaction: Compressor is switched off. Main PCB applies power to the compressor after 10 Minutes, Main PCB disables detection logic for 6 hours.

Purpose: Compressor protection from overload.

Most Likely Cause: High temperature, environmental condition, condenser fan error, poor air flow, dirty condenser, internal compressor problem, sealed system problem

Least Likely Cause: Main PCB

Constantly ON or Constantly Flashing LED Codes...

Constantly ON LED...

Definition: Main PCB Defect

Trip Logic: Main PCB has failed

Reaction: Compressor is switched off.

Purpose: Main PCB protection from overload

Most Likely Cause: Main PCB

Constantly Flashing LED...

Definition:12vDC Short

Trip Logic: Short on 12vDC Circuit is Detected.

Reaction: All power to the unit is turned off.

Purpose: Main PCB circuit protection.

Most Likely Cause: Short on the 12vDC circuit, evaporator fan, condenser fan, ice room fan, ice maker, etc

Thank lg app