INLET ERROR

Cause

Water supply faucets are not fully open, or low water pressure.

Water inlet hoses are kinked, pinched, or crushed.

Solution

Make sure that the water faucets are fully open.

Make sure that the hoses are not kinked, pinched or crushed behind or under the washer. Be careful when moving the washer during cleaning or maintenance.

Cause

Water inlet filters are clogged.

Solution

Clean the inlet filters.

Cause

Pressure sensor tube has small hole.

Solution

Replace pressure sensor assembly. The tube comes with the pressure sensor only.

DETAILS BELOW:

TESTING THE WATER INLET VALVE

The Main PCB does not detect that any (or not enough) water has flowed into the tub based off the pressure sensor frequency. |

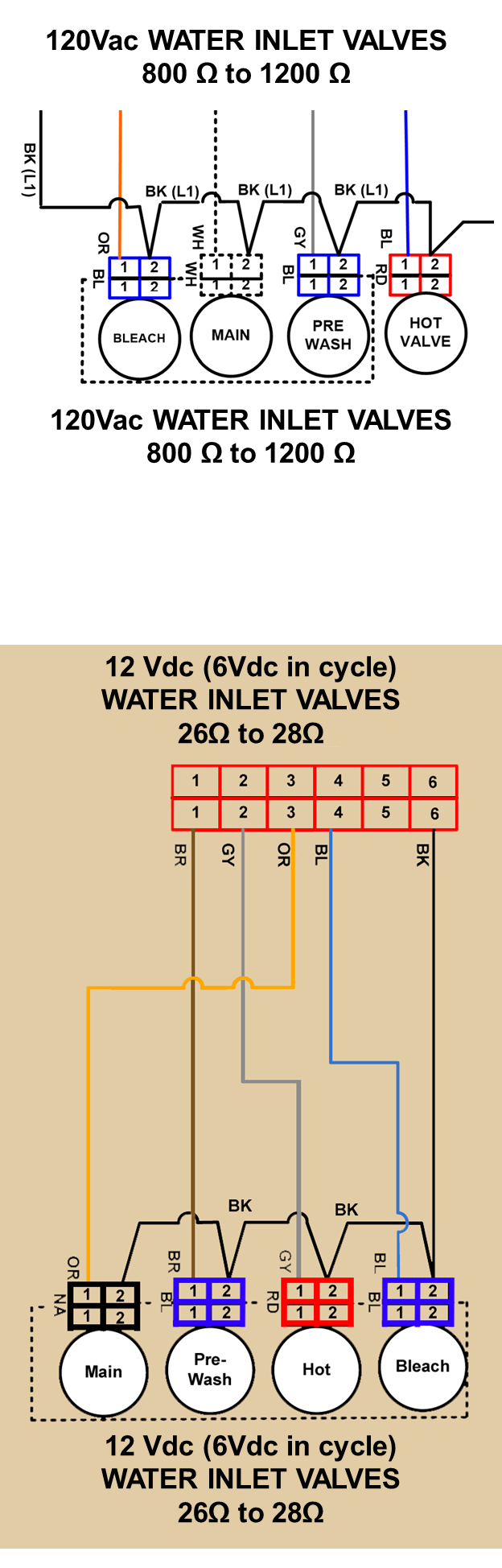

1.) Is the water supply valve turned on and completely open? Water supply pressure must be between 20 psi and 120 psi (138 – 827). If the water supply pressure is more than 120 psi, a pressure reducing valve must be installed. 2.) Are flood safe hoses being used? 3.) Unplug the unit. 4.) Disconnect the harness connections from the water valves. Test the resistance of each valve. Resistance should be approximately 800-1200Ω, for 120volt AC valves and 26-28Ω for DC valves *If an open is read, replace the valve.* 5.) Plug in the unit and activate test mode to cycle through all water valves. Voltage should read 120Vac, (Or 12v for DC models). 6.) If the valves are working in test mode, does the water level frequency decrease as water comes into the tub? If not, inspect the pressure sensor hose and air chamber for a crack or blockage. Pin 1 to Pin 3 should read 20 to 25 ohms. With the pressure sensor connected, measure voltage from Pin 2 to Pin 3 and Pin 2 to Pin 1. Both should read 2.5-3Vdc. For greater detail on how to check the pressure sensor please see the “PE” Error code article. |

10 Responses

RNN230914051266

RNN231002046273

Front load washing machine problem

Front load

RNN240111024292

RNN240126096018

RNN240226038534

Also check for drain hose inserted too far into standpipe. This could allow siphoning, causing the unit to drain as it fills. The pressure switch does not read pressure change and will throw an IE error code.

Yes drain hose inserted too far into j trap or taped to pipe causes siphon to check lift on drain hose and listen for water gurgling when you lift it if it gurgles it was under water and in a siphon condition secure zip tie drain line to hose to keep from dropping down or falling out

Ok